shipping container depot, Shipping Containers For Sale

Understanding Shipping Container Forklift Pockets

Understanding Shipping Container Forklift Pockets: Usage and Absence Explained

Shipping containers have revolutionized the transportation and storage industries with their robust design, versatility, and portability. Among their various features, one that stands out for its practicality is forklift pockets. However, it’s important to note that not all shipping containers come with these helpful additions. This article will delve into the specifics of shipping container forklift pockets, their uses, and reasons why some containers are devoid of them.

What are Forklift Pockets?

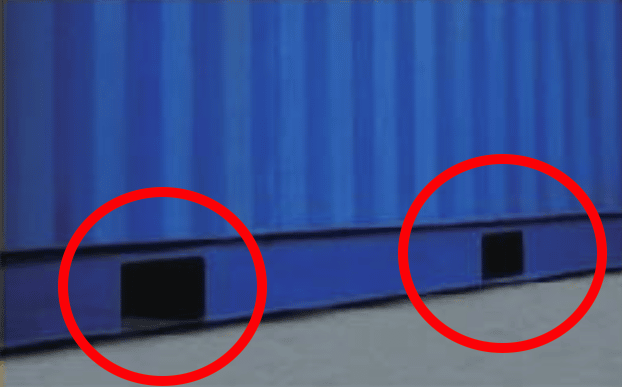

Forklift pockets are essentially rectangular openings located along the bottom side edges of a shipping container. These pockets are designed to accommodate the forks of a forklift truck, allowing for easy lifting, moving, and positioning of the container. They are generally about 350 mm high and 150 mm wide, although dimensions can vary slightly depending on the container’s size and design.

The Use of Forklift Pockets

The primary use of forklift pockets is to enhance the mobility of shipping containers. With the aid of a forklift, containers can be conveniently lifted off the ground and transported short distances within a yard, warehouse, or construction site. This ability significantly reduces the effort and time required for repositioning or relocating containers.

Forklift pockets also allow for safer and more secure handling of containers. When a forklift’s tines are inserted into the pockets, it provides a stable grip that minimizes the risk of accidental tipping or sliding during transportation. This enhanced stability is particularly crucial when containers are loaded with heavy goods, making forklift pockets an essential safety feature.

Additionally, forklift pockets can simplify the loading and unloading process. Containers with forklift pockets can be easily lifted onto and off from transport vehicles, which can be particularly advantageous in locations without specialized loading equipment.

Why Some Containers Don’t Have Forklift Pockets

While forklift pockets offer numerous benefits, it’s worth noting that not all shipping containers feature them. There are several reasons for this.

Firstly, the standard method for lifting and moving shipping containers over long distances or onto ships involves using specialized cranes that attach to the corner castings of the container. These cranes do not require the use of forklift pockets, which means that for long-distance transportation and shipping purposes, forklift pockets aren’t necessary.

Secondly, forklift pockets are not always suitable for lifting fully loaded containers. The weight capacity of many forklifts may not be sufficient to lift a heavy, fully laden container, making the pockets redundant in such cases. This is particularly true for larger containers, such as 40-foot models, which are often too heavy for forklift handling once loaded.

Finally, the inclusion of forklift pockets can slightly reduce the internal storage capacity of a container and may marginally increase its production cost. Therefore, some manufacturers opt to exclude them, particularly for containers intended for static storage use or long-distance transportation.

Forklift Pockets and ISO Standards

The International Standards Organization (ISO) has set specific dimensions for the forklift pockets on shipping containers. According to the technical specifications found on Flex-Box’s website, each forklift pocket is designed with a top plate that is 3 mm thick and a bottom plate that is 6.0 mm thick1.

However, while ISO provides guidelines for the construction of shipping containers, including forklift pockets, it does not specify exact dimensions for these pockets. The size can vary depending on the type and size of the container and its intended use. For instance, the net opening size of the fork pocket of offshore containers should not be less than 200mm × 90mm2.

It’s also important to note that forklift pockets are typically only installed on 20′ containers, arranged parallel to the centre of the container in the bottom side rails3. 40′ containers often do not include forklift pockets due to their weight when loaded.

In conclusion, while there are general guidelines for the construction of forklift pockets on shipping containers, the exact dimensions can vary.

Quick Quote

Quick Quote